Engineering Plastic Diaphragm Pump

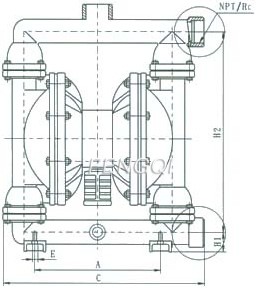

Engineering Plastic diaphragm pump diaphragm pump Drawing

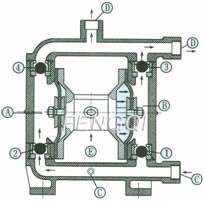

Structure Of Engineering Plastic diaphragm pump diaphragm pump

Summary

QBY Engineering Plastic diaphragm pump not only can exhaust the flow liquid,but also can convey some uneasy flowed medium,with the merits of self-pumping pump,diving pump,shield pump,slurry pump and impurity pump etc:

- It s unnecessary to pour the drawing water,the suction lift reaches 7 m height,the delivery lift reaches 70 m length and the export pressure ≧6kgf/cm2;

- Wide flow and good performance.The diameter allowed to pass the max grain reaches 10 mm.The damage is very less to the pump while exhausting the slurry and impurity.

- The delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment(the pneumatic pressure adjustment is between 1-7 kgf/cm2) ;

- This pump has no rotary parts and no bearing seals.The diaphragm will completely separate the exhausted medium and pump running parts,working medium.The conveyed medium can t be leaked outside.Thus it will not cause the environmental pollution and human body safety dangerous whils exhausting the toxin and flammable or corrosive medium.5, No electricity. It s safe and reliable while using in the flammable and explire places.

- It can be soaked in medium.

- It s convenient to use and reliable to work..Only open or close the gas valve body while starting or stopping.Even if no medium operation or pausing suddenly for long time because of accident matters,the pump will not bedamaned caused by this.Once over-loading,the pump will automatically stop and possesses the selfprotection function.When the load recovers normally,it also can start automatically.

- Simple structure and less wearing parts.This pump is simple in structure,installation and maintenance.The medium conveyed by the pump will not touth the matched pneumatic valve and coupling lever etc.Not like other kinds pumps,the performance will drop down gradually because of the damages of rotor,gear and vane etc.

- It can transmit the adhesive liquid(the viscosity is below 1000 centipoise).

- This pump needn t the oil lubricant.Even if idling,it has any influence to the pump.This is a characteristic of this pump.

Working principle

There installs each diaphragm in both aligned working cavities(A) &(B),which can be connected tonether with a central coupling lever.The compression air enters the air distribution valve from the air entrance of the pump,draw the compression air into one cavity through the air distibution mechanism,push out the diaphragm movement in the cavity.The gas in another cavity will be drained.Once reaching the stroke terminal,the air distribution mechanism will automatically draw the compression air into another working cavity,push out the diaphragm to move towards the opposite direction,so as to let the both diaphragms continuously reciprocate motion in synchronism. The compression air enters the air distribution valve from(E)shown as the diagram,let the diaphragm piece move towards the right direction.And the suction force in(A)chamber lets the medium flow into from(C)entrance,push out the ball valve(2)to enter(A)chamber,the ball valve(4)will be locked due to the suction force;The medium in(B)chamber will be pressed,push out the ball valve(3)to flow out from the exit(D).Meanwhile,let the ball valve(1)close,prevent backflow.Such movement in circles will let the medium uninterruptedly suck from(C)entrance and drain feom(D)exit.

Main usage

- The pump can suck the peanut,pickles,tomato slurry,red sausage,chocolate,hops and syrup etc.

- The pump can suck the paint,pigment,glue and adhesive etc.

- The pump can suck various glazed slurries of tile,porcelain,brick and chinaware etc.

- The pump can suck various grinding materals,corrosive agent and clean the oil dirt etc.

- The pump can suck various toxin and flammable or volatility liquid etc.

- The pump can suck various wedge water,cement slurry and mortar etc.

- The pump can suck various strong acid,alkali and corrosive liquid etc.

- It can be used as a front-step transmission device of the solid and liquid separation equipment.

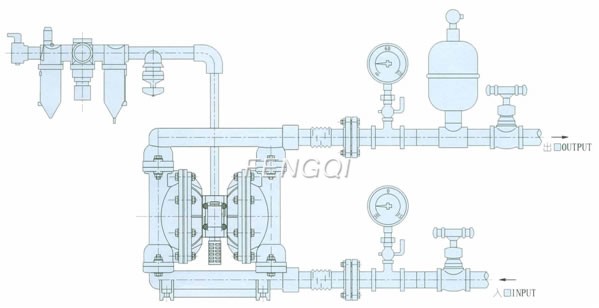

System connection schematic diagram

Engineering Plastic diaphragm pump System connection schematic diagram

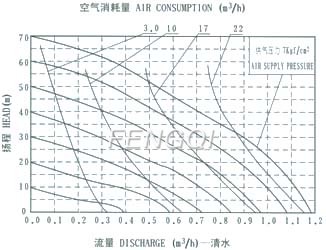

DISCHARGE (m3/h)-water

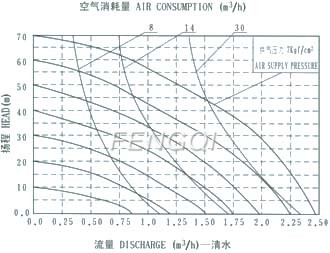

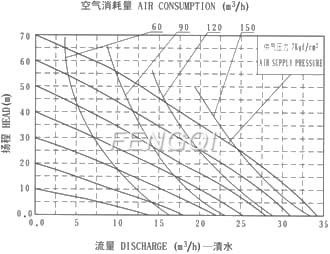

QBY-10 diaphragm pump

DISCHARGE (m3/h)-water

QBY-15 diaphragm pump

DISCHARGE (m3/h)-water

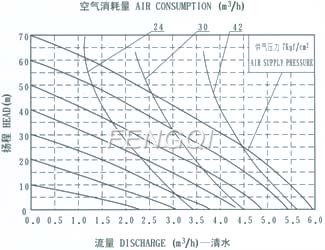

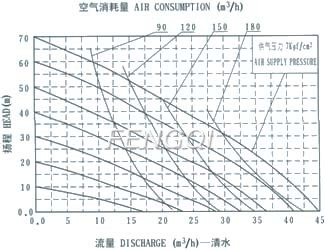

QBY-25 diaphragm pump

DISCHARGE (m3/h)-water

QBY-40 diaphragm pump

DISCHARGE (m3/h)-water

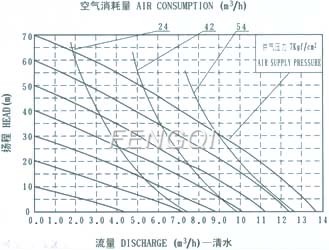

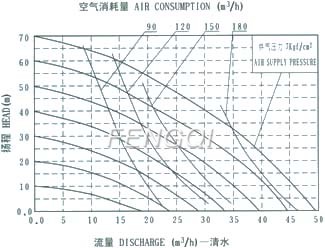

QBY-50 diaphragm pump

DISCHARGE (m3/h)-water

QBY-65 diaphragm pump

DISCHARGE (m3/h)-water

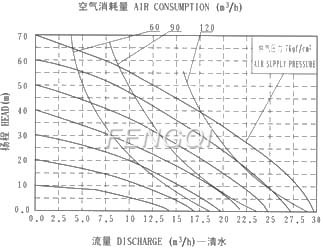

QBY-80 diaphragm pump

DISCHARGE (m3/h)-water

QBY-100 diaphragm pump

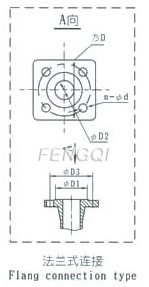

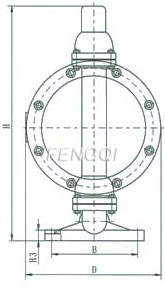

Drawing of setting data

Engineering Plastic diaphragm pump diaphragm pump Drawing 3

Engineering Plastic diaphragm pump diaphragm pump Drawing 2

Engineering Plastic diaphragm pump diaphragm pump Drawing 1

Table of setting data

| Model | A | B | C | D | E | H1 | H2 | H3 | H | Screw | Flange | |||||

| NPT/RC | D1 | D2 | D3 | D | n | g | ||||||||||

| QBY-10 | 130 | 50 | 220 | 145 | 10 | 39 | 195 | 10 | 270 | 1/2 | - | - | - | - | - | - |

| QBY-15 | 130 | 50 | 220 | 145 | 10 | 39 | 195 | 10 | 270 | 1/2 | - | - | - | - | - | - |

| QBY-25 | 245 | 160 | 360 | 250 | 12 | 63 | 360 | 36 | 470 | 2 | - | - | - | - | - | - |

| QBY-40 | 245 | 160 | 360 | 250 | 12 | 63 | 360 | 35 | 470 | 11/2 11/4 | - | - | - | - | - | - |

| QBY-50 | 335 | 220 | 540 | 345 | 16 | 88 | - | 25 | 720 | - | 90 | 50 | 110 | 130-130 | 4 | 14 |

| QBY-65 | 335 | 220 | 540 | 345 | 16 | 88 | - | 25 | 720 | - | 110 | 65 | 130 | 130-130 | 4 | 14 |

| QBY-80 | 425 | 250 | 570 | 450 | 18 | 110 | - | 32 | 900 | - | 125 | 80 | 150 | 160-160 | 4 | 18 |

| QBY-100 | 425 | 250 | 570 | 450 | 18 | 110 | - | 32 | 900 | - | 145 | 100 | 170 | 160-160 | 4 | 18 |

Preformance parameter

| Model | Discharge (m3/h) |

Head (m) |

Exit pressure (kgf/cm2) |

Sucked Lift (m) |

Max grain Dia (mm) |

Max pressure (kgf/cm2) |

Max air consumption (m3/min) |

Materials | ||||

| ZL104 | 1Cr18 Ni9Ti |

HT200 | Enhanced Polypr opyene |

F4 F46 (EFP)PO |

||||||||

| QBY-10 | 0~0.8 | 0~50 | 6 | 5 | 1 | 7 | 0.3 | * | * | * | * | / |

| QBY-15 | 0~1 | 0~50 | 6 | 5 | 1 | 7 | 0.3 | * | * | * | * | / |

| QBY-25 | 0~2.4 | 0~50 | 6 | 7 | 2.5 | 7 | 0.6 | * | * | * | * | |

| QBY-40 | 0~8 | 0~50 | 6 | 7 | 4.5 | 7 | 0.6 | * | * | * | * | * |

| QBY-50 | 0~12 | 0~50 | 6 | 7 | 8 | 7 | 0.9 | * | * | * | / | * |

| QBY-65 | 0~16 | 0~50 | 6 | 7 | 8 | 7 | 0.9 | * | * | * | / | * |

| QBY-80 | 0~24 | 0~50 | 6 | 7 | 10 | 7 | 1.5 | * | * | * | / | / |

| QBY-100 | 0~30 | 0~50 | 6 | 7 | 10 | 7 | 1.5 | * | * | * | / | / |